Description

Fully automatic sealing powder packaging machine, suitable for small bags of milk powder/protein powder/matcha powder

Model: DS-320C

1. Packaging Bag: Small Bags

2. Applications: Daily Chemicals, Pharmaceuticals, Food, Pigments, Powders, etc.

3. Applicable Materials: Laundry Detergent, Coffee Powder, Milk Tea Powder, Tea Powder, Matcha Powder, Protein Powder

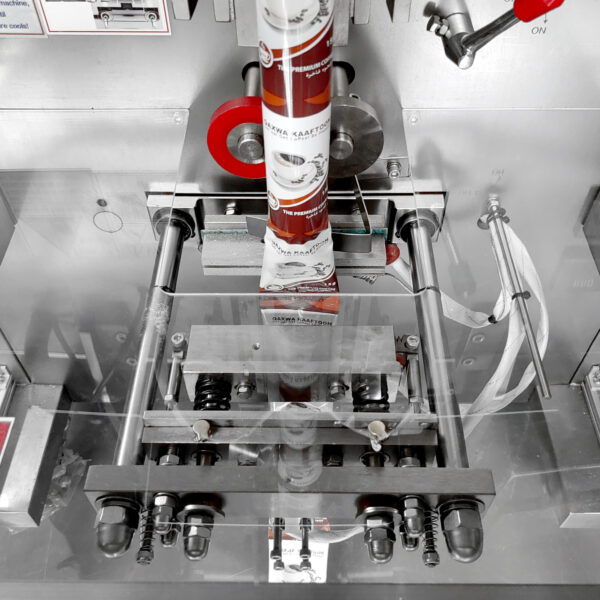

4. Bag Types: Back Seal, Three-Side Seal, Four-Side Seal, Special-Shaped Bags, Strip Bags

5. Process: Fully Automatic Loading, Bag Making, Filling, Sealing, Slitting, Counting, and Hot Pressing

6. Operating Principle: This machine utilizes a combination of mechanical transmission and PLC control. The touchscreen control allows for stepless speed regulation, parameter setting, output counting, and comprehensive control of operating status, ensuring easy and user-friendly operation.

7. Service: Our factory can customize packaging machine solutions based on your needs and provide on-site and online after-sales service.

Machine Characteristics

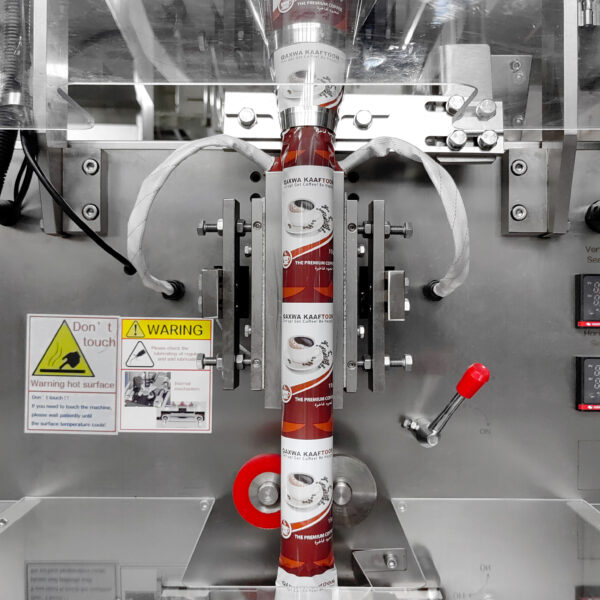

1. Durable, Clean, and Safe:

The machine body is constructed of high-quality stainless steel, which is not only corrosion-resistant and easy to clean, meeting food hygiene standards, but also significantly extends the equipment’s lifespan, fundamentally reducing your long-term maintenance and replacement costs.

2. Smart and Intuitive, Easy to Learn:

Equipped with a color, multi-language touchscreen, the interface is intuitive and the operation logic is simple. New employees can quickly get started, significantly reducing training effort and costs, effectively addressing employment challenges.

3. Safety First, Risk Control:

A prominent one-touch emergency stop button provides instant response in any emergency, maximizing operator safety, preventing accidental equipment damage, and minimizing potential personal injury and financial losses.

4. Highly Efficient Output, Leading Costs:

Exceptional packaging speed significantly increases daily output, helping you easily handle large-volume orders and shorten delivery cycles. Large-scale production effectively reduces unit costs, giving you stronger price competitiveness in the market.

5. Labor-Saving, Quality-Enhancing, and Efficient:

The fully automated process significantly reduces reliance on skilled labor, directly reducing labor costs. At the same time, the machine can ensure high consistency and high yield of packaging quality, effectively reduce material waste, and comprehensively improve your production efficiency.