Description

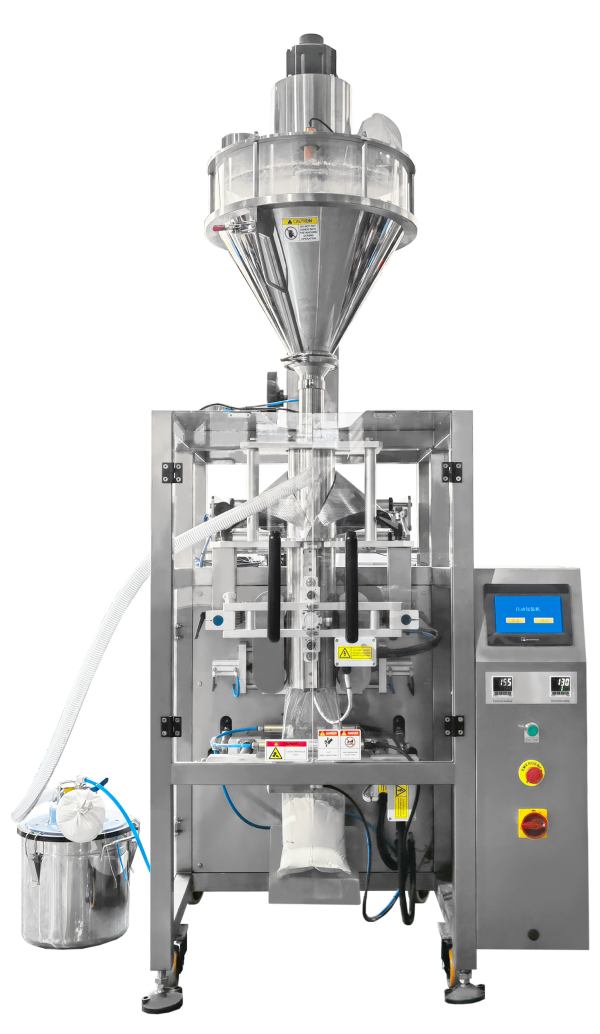

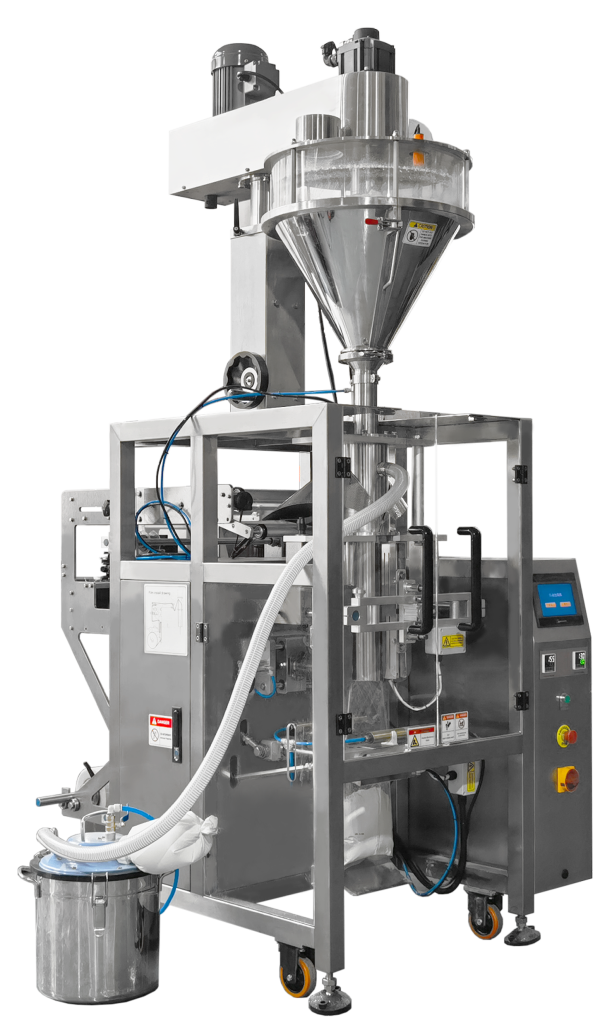

matcha tea powder bag packaging machine

Are you looking for a bagging machine which can packing from 100g-5000g powder product by full automatic?

Do you trying to find a economical packing machine model but with reasonable price and assured service?

Do you trying to find a economical packing machine model but with reasonable price and assured service?

Our Bread/Cooking/Cake/Maize/ Rice/Milling/Chicken/Recipe/Corn Organic Flour Weighing Filling Bagging Package Packaging Packing Machine can be your first choice!Our powder packing machine is suitable for most of the non-sticky powder product (such like: flour, starch, coffee powder, etc)

If your product it is sticky powder type which similar like: milk powder, coconut powder, spice powder, chocolate powder,etc.

We suggest coating with Teflon material for better meatering and filling.Machine adopted high precision auger filling system which guarantee packing tolerance within 1% ( depending on product)

Besides, the auger is very easy to taking out and installation back within 10 minutes even a new user.

If your product it is sticky powder type which similar like: milk powder, coconut powder, spice powder, chocolate powder,etc.

We suggest coating with Teflon material for better meatering and filling.Machine adopted high precision auger filling system which guarantee packing tolerance within 1% ( depending on product)

Besides, the auger is very easy to taking out and installation back within 10 minutes even a new user.

User just need put on the packing film, then machine will automatic to forming bag, filling material with the setting weight, printing on the production / expirtation / batch number and sealing the bag tightness. Function like: nitrogen gas feeding and linked bag, hanging hole punch also available!

Packaging bag type

Features

1.Chinese and English touch screen display, intuitive and simple operation

2.PLC computer control system, the operation is more stable, and any parameter can be adjusted without stopping the machine

3.Ten qroups of parameters can be stored, and the replacement of varieties is more accurate

4.The servo motor is used to pull and touch, and the positioning is more accurate

5.ndependent temperature control system, the accuracy can reach ±1°C

6.The temperature of horizontal and vertical sealing can be controlled independently, which can be wellapplied to various packaging

materials such as composite film and aluminum film

7.The packaging styles are diversified, such as back sealing, gusseting,connected bag , punching, hole etc

8.The production of bag making, sealing, packaging, and date printing is completed at one time

9.he working environment is clean and the noise is low